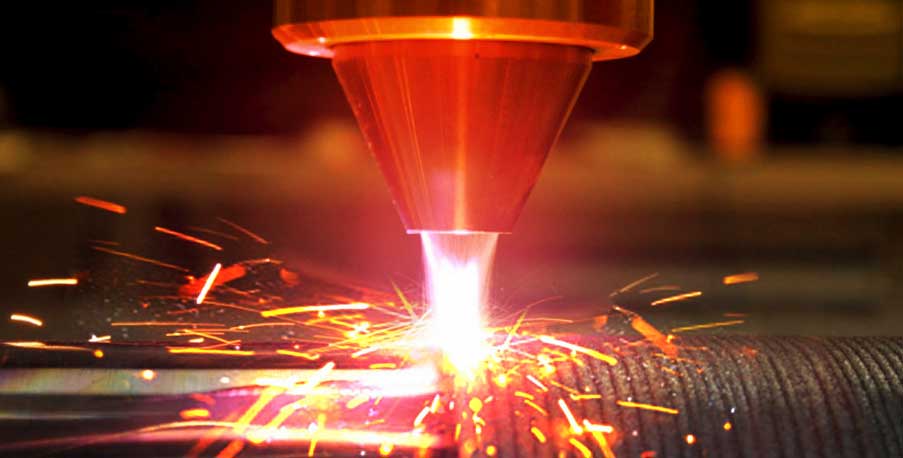

Laser cladding by a powder injection is the state of the art technology in weldings that our company has been widely used since 2012 and was the first that introduced this method into the Greek Market. This procedure has been commonly used in the shipping and industrial fields, such as rapid manufacturing, spare parts repair, surface hardening/coating, and so many more applications. CNC cladding cell machine, in conjunction with Laser cladding tech, makes everything repairable and feasible.

Advantages

Perfect metallurgically bonded and fully dense coatings.

Minimal heat affected zone and low dilution between the substrate and filler material resulting in functional coatings that perform at the reduced thickness, so fewer layers are applied.

Fine, homogeneous microstructure resulting from the rapid solidification rate that promotes wear resistance of carbide coatings

Extended weldability of sensitive materials like carbon-rich steels or nickel-based superalloys that are difficult or even impossible to weld using conventional welding processes

Post-weld heat treatment is often eliminated as the small heat-affected zone minimizes component stress.

Applications

- Shafts-piston rods etc.

- Turbocharger parts repair- rotor, compressor wheel, and housing

- Four-stroke steel/cast iron pistons

- Steam turbines- rotor, casing, pinion shaft

- Pump shafts

- Various rotor shafts

- Blades

- Impellers