LOUKAS was founded by the most famous-qualified welder in South Europe, Loukas K. Kontoyiannis.

The man that defined an era in Greeks about the welding techniques, he taught them well the welder perception practically and theoretically.

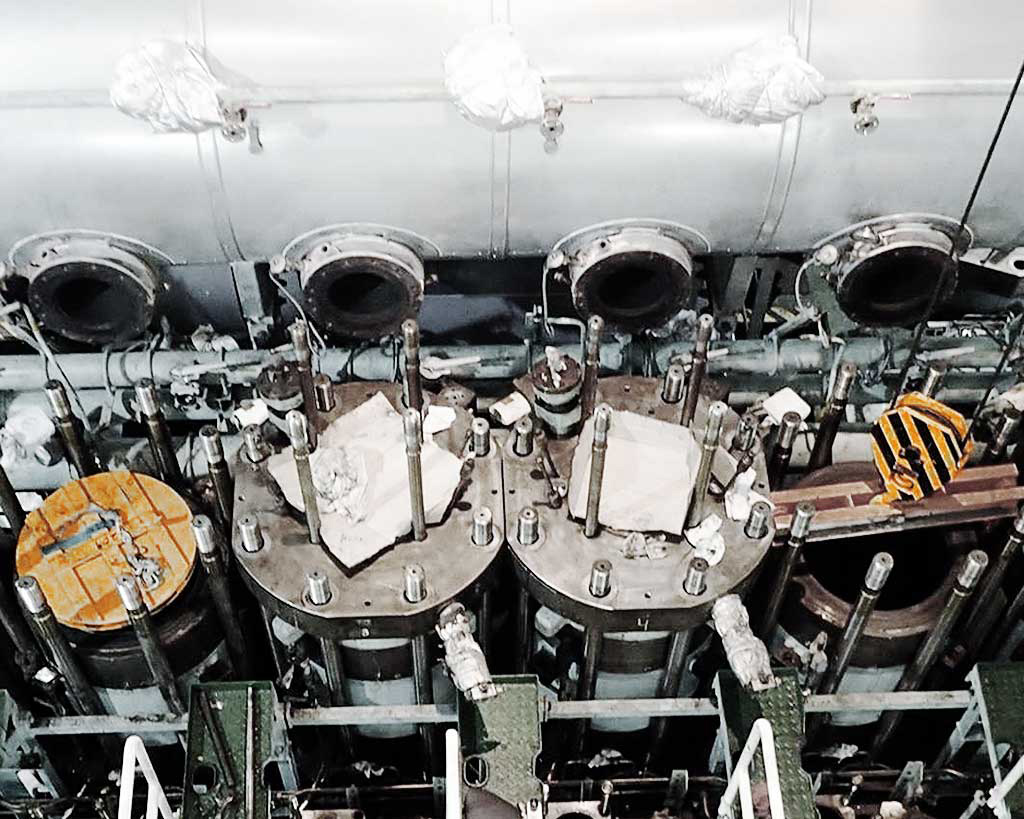

Marine

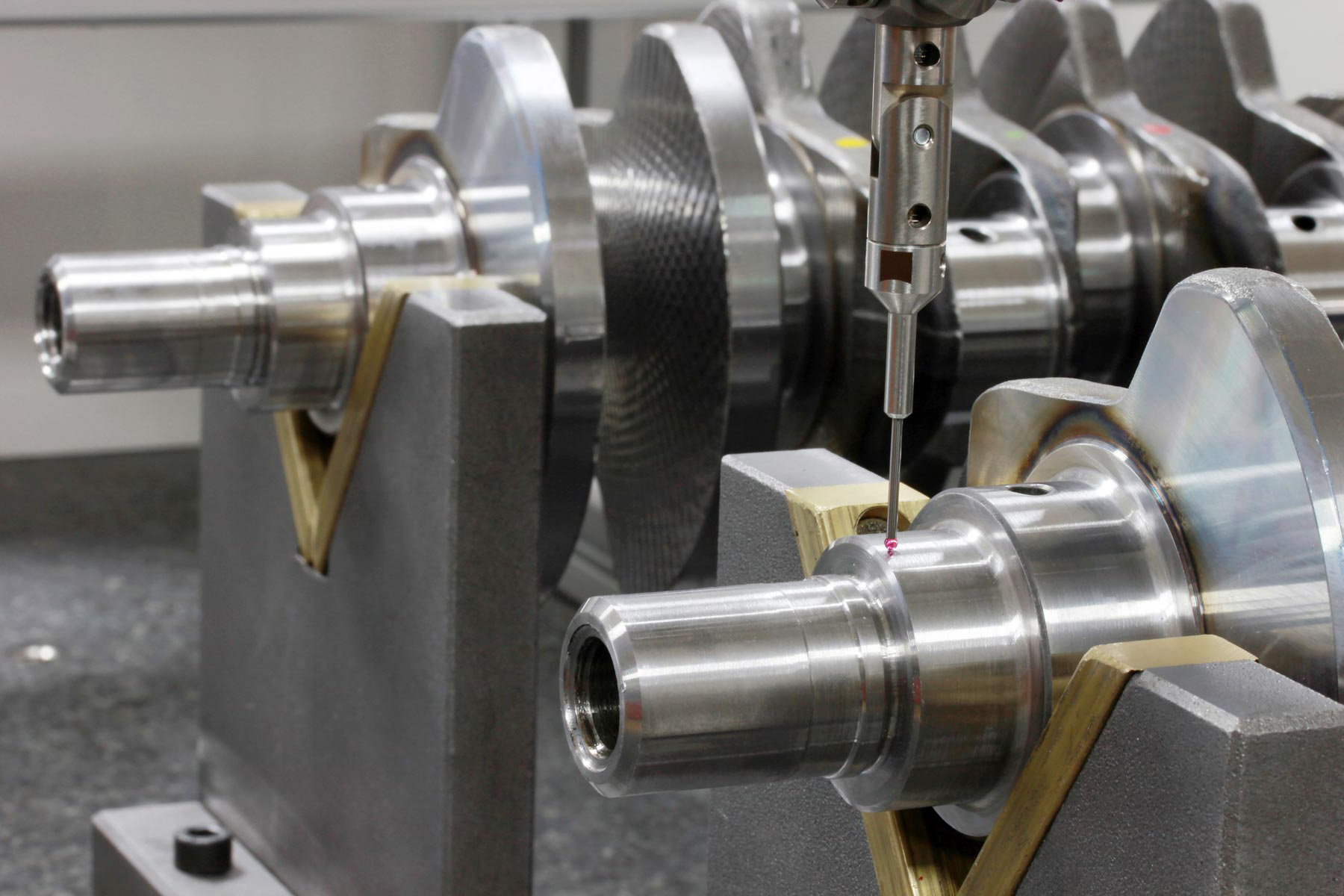

- Maintenance/Overhauling, Repair

- Onboard Mechanical Engineering Services

- Spare Parts

- Technical Consulting

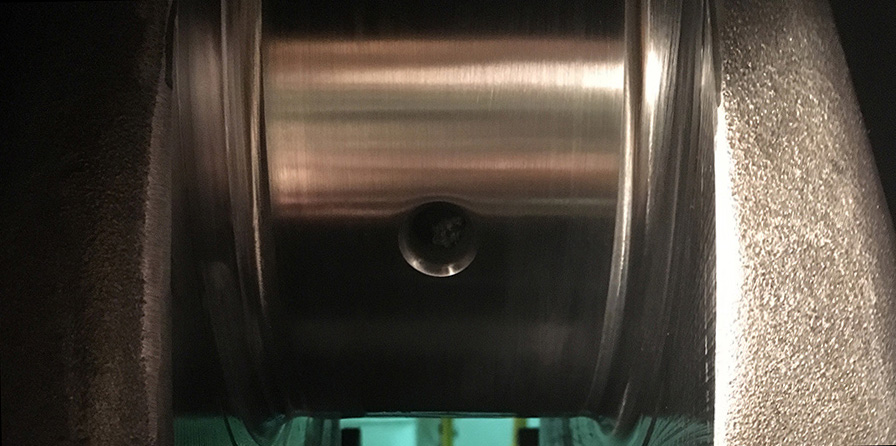

Power Plants

- Oil, Gas

- Maintenance Repair

- Spare Parts

- Technical Service

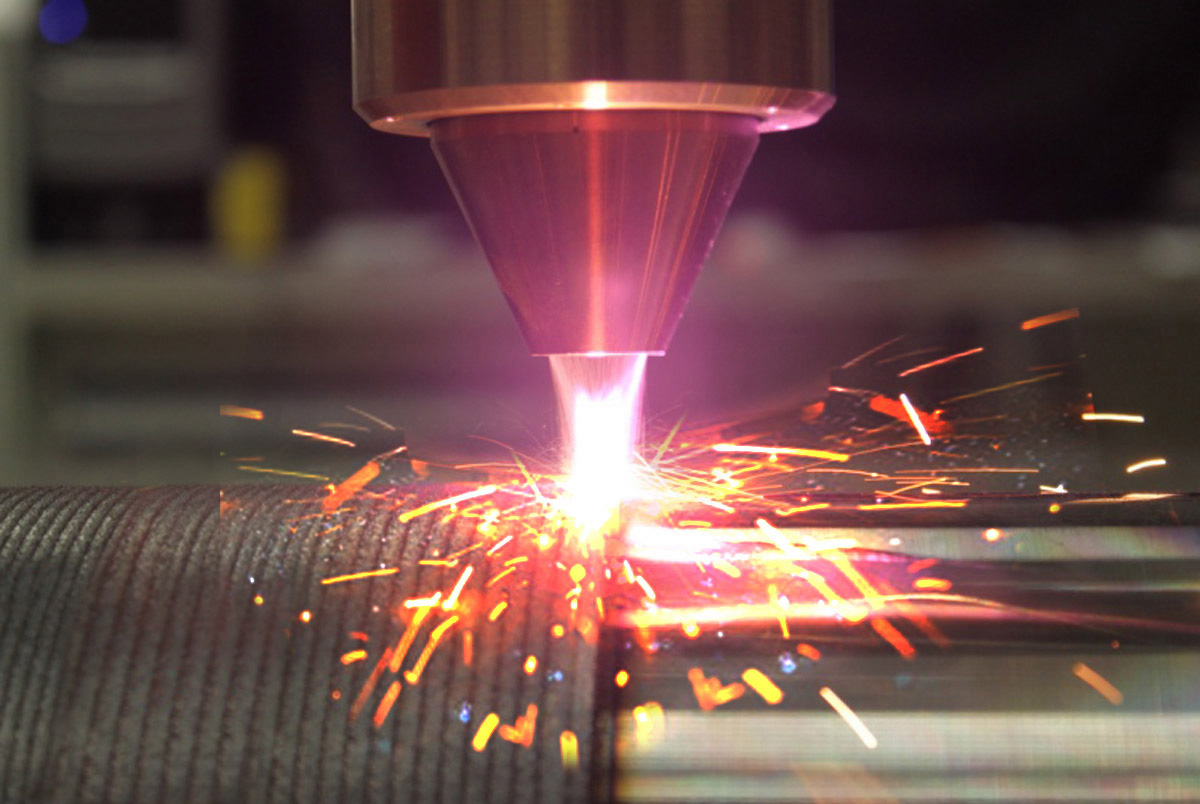

Engineering

- Advance Technologies

- Tailor-made Concepts

- Comprehensive Support

Network

- 24/7/365 Support

- Intervention for Domestic Network / Immediately (Greece)

- Intervention Internationally / Upon Request

About us

Request a quote

Please send us anything in order to assist you with our services or any additional info.

Why chose us

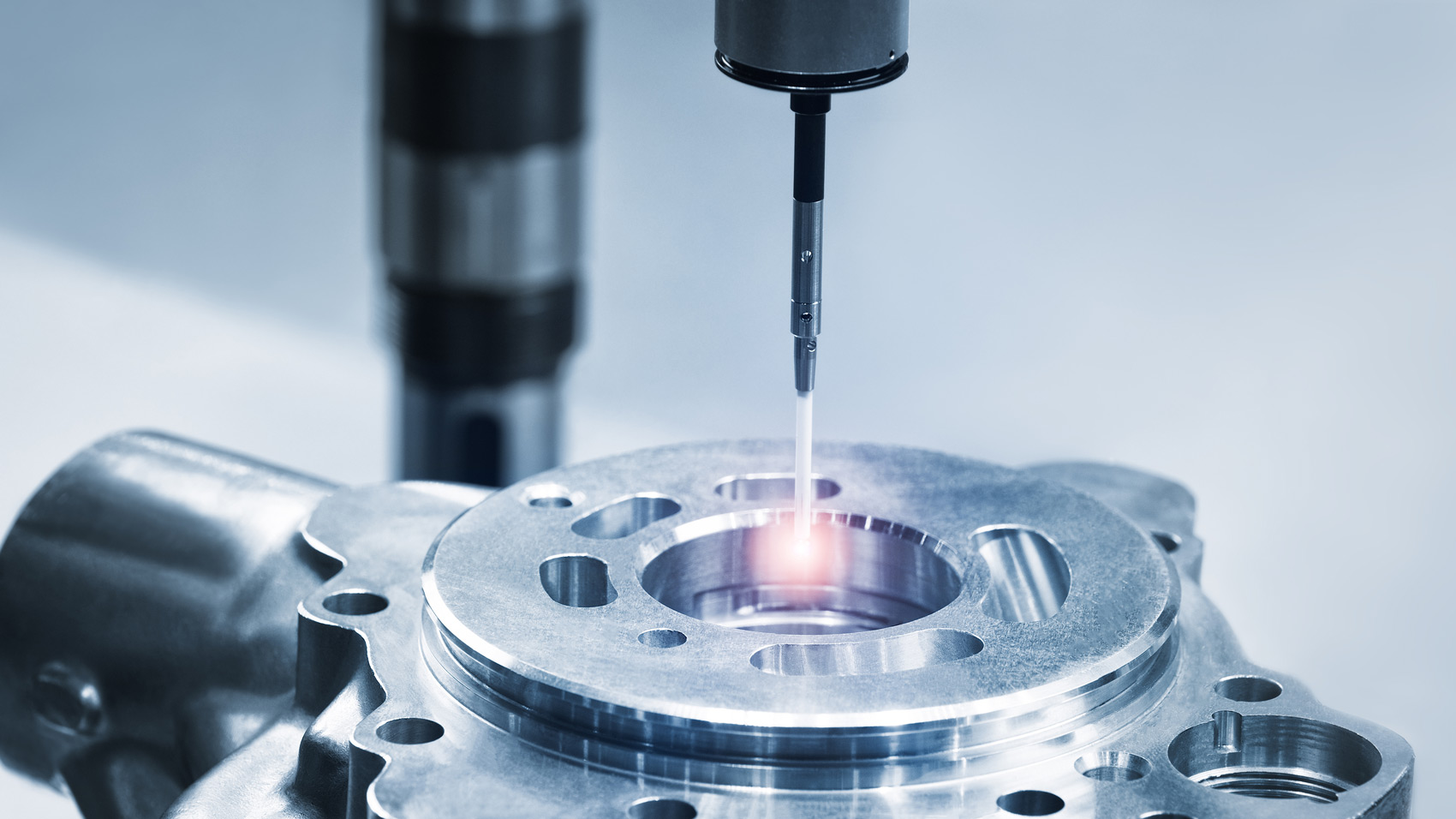

Experience of more than 70 years in the shipping and industrial sector.

A wide variety of services under the umbrella of a brand that is well known for what is capable.

Reconditioning Services, Fabrication, Spare Parts, Technical Consulting.

LOUKAS is a label that means truth, trust, and professionalism.

To enhance and remain who we are. We always serve the shipping and industrial sector through engineering services without divergence.

To be and act as true professionals and lead the field where we are good at.

Nothing more, nothing less.

Anything Loukas K. Kontoyiannis has ever envisioned to become a reality.

72

Years In Market

30

Workers Team

2345

Projects Done

Blog company

INTEGER CONGUE ELIT